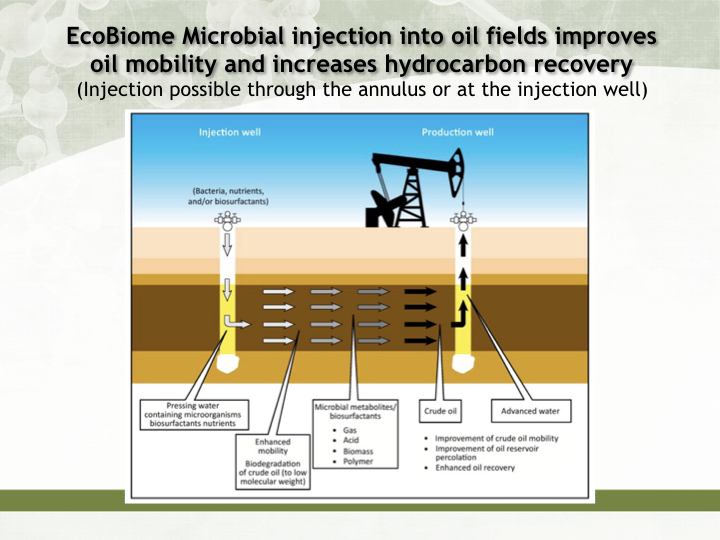

The microbes in EcoBiome Next Gen are strong and potent producers of CO2 off-gas, which is a metabolic by-product of hydrocarbon conversion. The CO2 helps to re-pressurize the reservoir to allow for oil that was once immobile to become mobilized in the formation.

MORE Q&A ON MEOR

Contact us for more Information

-

Related to microbial activities that produce "Gases", How does this product can solve "Reservoir Re-pressurization"?

-

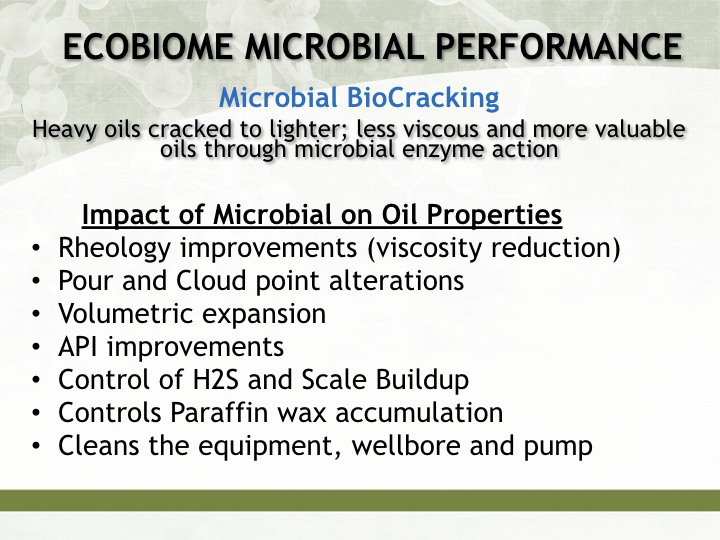

Related to "Bio-emulsifier" products, how effective this product compare to common PPD (Pour point depressants) chemical to reduce pour point temperature?The biosurfactant produced from the bacteria are similar to Rhamnolipids and Glycolipids. They are effective and work to decrease Interfacial Tensions in the oil/water interphase. They are as effective as chemical and synthetic based (esp. ethanolic) surfactants. Additionally, the bacteria are continuously producing biosurfactants once in the formation, whereas chemical surfactants are quickly used up and degrade under the difficult environments of the reservoir.

-

How does the "Biomass formation" product works?The greater the biomass then the greater their metabolic byproducts in the reservoir (CO2 gas, polymer, biosurfactants and organic acids) will be in the formation. The biomass can also plug water channels that have formed to re-pressurize the formation and to push new water flow into higher oil areas.

-

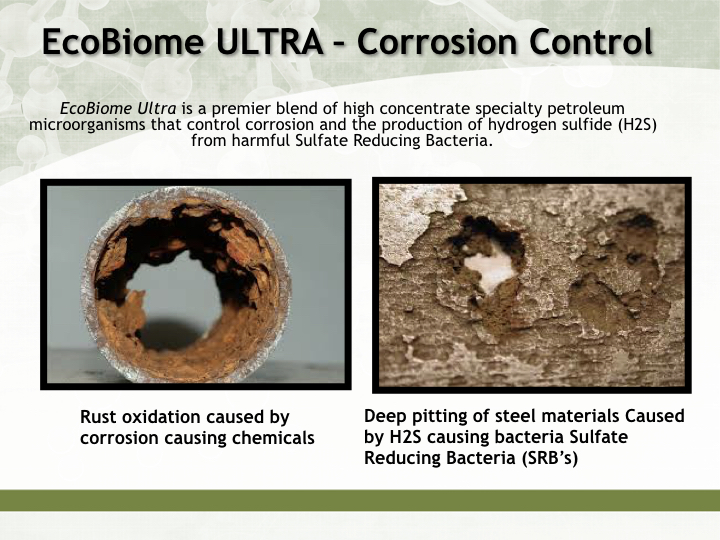

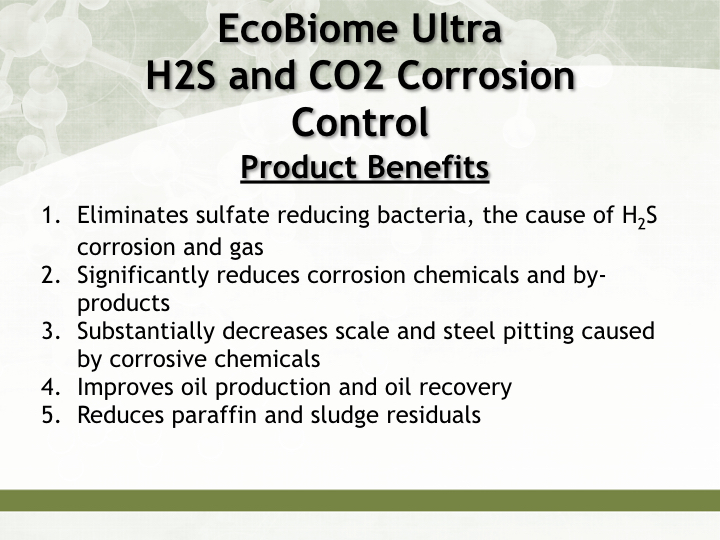

Please list some experiences with successful and failure story of increase oil production. If any, what are the causes of that failed story?The vast majority of trials and commercial field applications are successful with 10-50% increases in oil production. We also see substantial decreases in H2S and corrosion as well as cleaning of paraffin wax. Most of the time when we have failures is due to other strong chemicals, like biocides being injected at the same time or soon after adding our microbes. Biocides and strong chemicals may kill off microbes and keep them from colonizing.

-

By experience, which one is more effective application, by huff and puff or continuous injection (water flood-MEOR)?Generally continuous injection is more effective because it allows for good and healthy establishment of the petroleum microorganisms in the rock pores of the reservoir. We do have customers who introduce the product via Huff and Puff and still have good success. The preference is continuous injection though.

-

How long the microbes can stay alive since the day of dispatch from USA to Indonesia?We ship the microbes to our partner, Sentinel Mikroba Indonesia(SMI) in a dry powder form and the shelf life is 5 years. SMI will then blend it into concentrated liquid for the client. As a liquid our product has a shelf life of 2 years.

-

How does the delivery mechanism of the microbes? Is it in a container with special conditioning system?As mentioned above the shipment to SMI warehouse is as package and ship in poly pouches and/or in fiber drums that are sealed. Our Partner SMI will blend and mix it using an agreed blending protocols for injection. The concentrated solution will be brought to field for injection using details protocols and instruction to inject the solution into the well. SMI can also provide injection services if so required by clients.

-

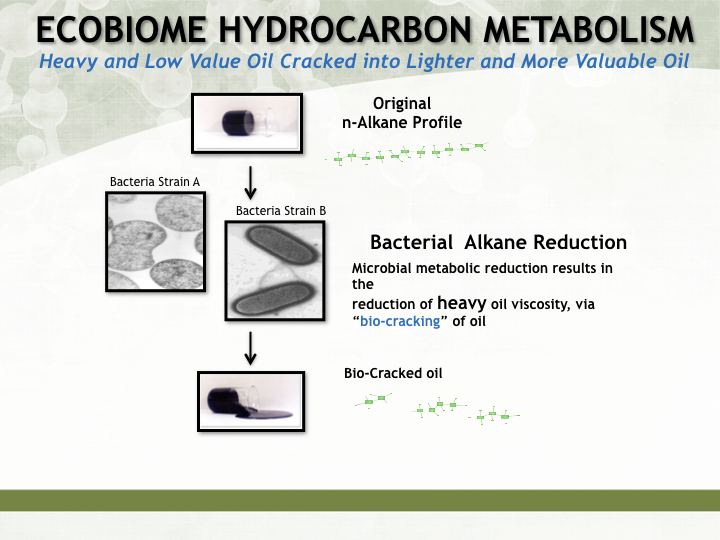

Can we quantitatively make an estimate of production gain from this MEOR treatment? Is that using empirical correlation or statistical modelling?It is difficult to obtain a solid estimation in the beginning without having an idea whether the microbials have successfully colonized the reservoir formation. Once they have successfully colonized the reservoir then they will be able to bio-crack the heavy oil and begin releasing lighter and more valuable chains of oil for production. Generally we see on average of 20-40% above historical baselines.

-

In field cases, Sentinel were successful on wells with production rate < 10 bbls/day. Do you think your MEOR will be good for big wells with base production > 100 bopd as well? If yes, will a larger MEOR volume be needed?Yes, we do believe that the product will help substantially in larger producing wells (>100 BBL/day). There are a variety of potential issues in the formation that the microbes can remediate and control, including corrosion. There will need to be a larger volume injected but it will be manageable and reasonable.

-

What are the suitable formation rocks for your MEOR product?We work both in limestone and sandstone formations. The microbes can colonize many types of formations.

-

Please list any suitable permeability, temperature, salinity and pH range of Sentinel product.The microbes form spores that can resist high temps and environmental ranges including salinity, pH and temperatures. The microbes are 1.5 micrometers in diameter (very small) and can withstand pH range of 1 – 10, temps of up to 120C and high salinities over 25%.

-

How much is the typical injection volume and the injection percentage for a MEOR project?We recommend an initial injection of 110-165 gallons followed by a water flush of 1:10 ratio. Then a weekly injection of 25-55 gallons of microbes followed by a water flush (1:10 ratio).

-

How far the injection radius for Huff and Puff operation and water flood-MEOR scenario?The microbes, once injected have flagella which are whips surrounding its outer wall that allow it to move and mobilize. The bacteria move from day to day at a rate of 3-5 feet per day. Therefore, even though the injection radius may be small, the bacteria will move to different points to release oil.

-

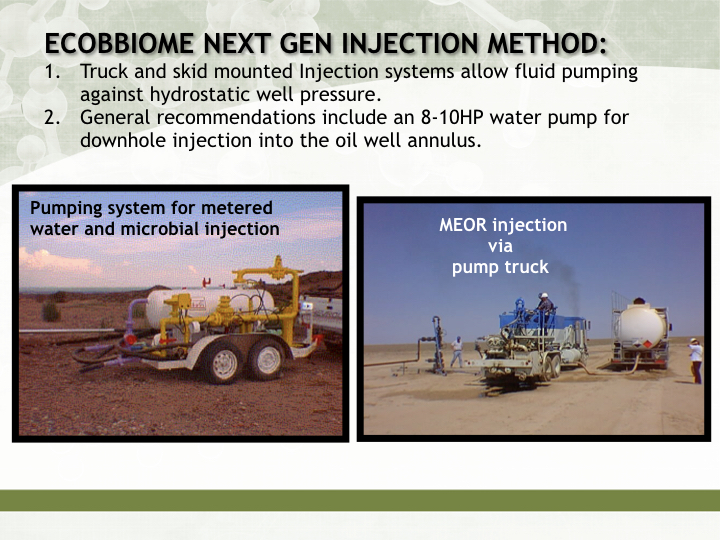

How much the typical pumping rate per well to handle huff and puff MEOR?We generally use a standard pump of 4-6 HP to inject. Larger and higher flow pumps can also be used. As a rule, the pump needs to be greater than the hydrostatic pressure of the well pushing back.

-

What is the range of injection rate for water flood-MEOR?The microbes can be injected solely at the production well through the annulus of the well, or can be injected through an injector pump that reaches multiple wells. The injection volumes will have to be multiplied by the number of zones or wells that are reached.

-

What is the estimated price to recover additional one barrel (cost/bbl)?Microbial EOR is typically the lowest priced and mist economical procedure to generate new production. On average it may cost$2.5-$5/incremental barrel versus much higher prices for other technologies. Equipment may consist of injection pumps, mix tanks with agitation to enable injection into the annulus of the well.

-

Does Sentinel has special data needed from the operating company for your MEOR project?We have a well data sheet that is always helpful so that we can have a better understanding of the history of the well…including previous chemicals injected into the well.